For diesel engine, most user or engineer will talk about cylinder pulling sometimes. But do they all understand what is cylinder pulling? What is cylinder pulling in diesel genearotrs? What situation can be set as cylinder pulling? What is the reason why we will meet cylinder pulling? How to solve this kind of problem?

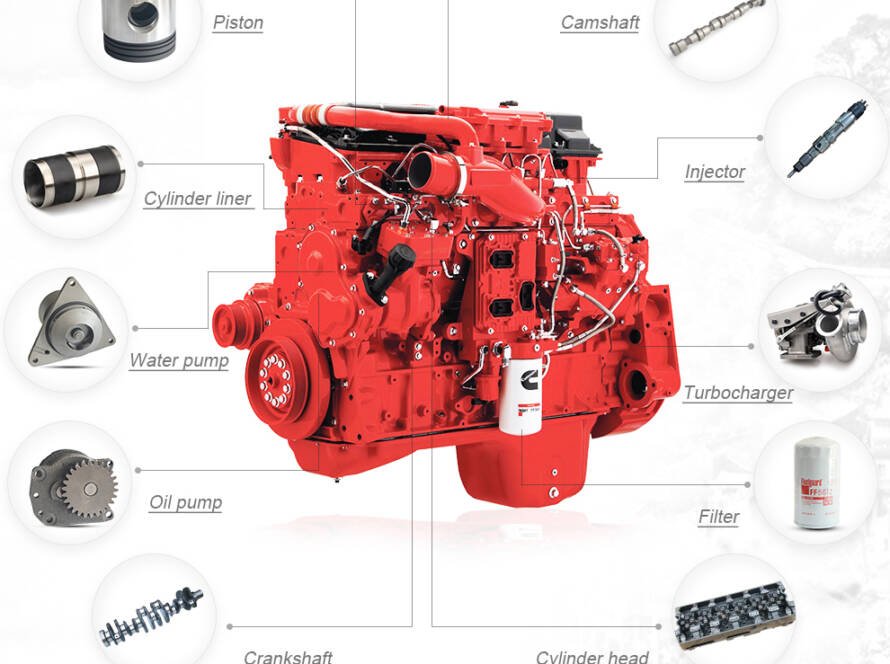

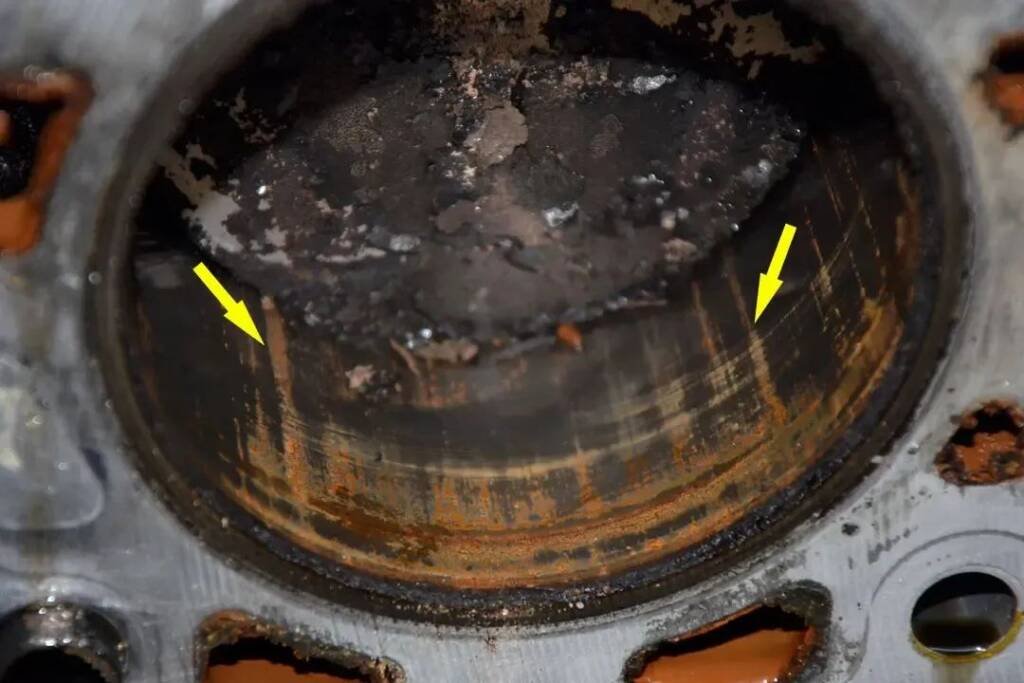

1.What is engine cylinder pulling?

Cylinder pulling is a professional term for engine maintenance. Engine cylinder pulling refers to the inner wall of the cylinder in the piston, piston ring movement range, there is a clear longitudinal or mass of mechanical scratches and scuffing, serious fusion wear occurs. In other words, the interruption of the oil film between the piston and the cylinder liner is the main reason for cylinder pulling. Once the oil film between the piston and the cylinder liner is interrupted, the two metals produce dry friction, resulting in cylinder pulling.

2. What are the hazards of engine pulling?

Abnormal engine noise, oil pressure too low, engine oil passage is clogged, will cause the engine under the exhaust serious, the pressure inside the engine crankcase increases, and in serious cases, it will cause an explosion inside the engine crankcase.

3. What causes the cylinder pulling?

The main reasons for cylinder pulling are as follows:

(1)The piston ring clearance is too small. If the piston ring opening clearance, side clearance or backlash is too small, the engine works when the piston ring thermal expansion jammed, and the cylinder wall pressure is very tight, or piston ring fracture, it is easy to pull out grooves in the cylinder wall.

(2)The piston pin out. Due to the piston pin spring is not installed or fall off, broken, the piston pin in the movement out, it is easy to pull the cylinder wall, resulting in cylinder gas to the crankcase.

(3)The piston cylinder clearance is too small or too large. If the material of the piston is bad, the manufacturing size error is too large, or the piston is deformed after assembling the piston pin, resulting in the piston and cylinder mating clearance is too small, the piston is stuck after thermal expansion, which in turn pulls the cylinder wall.

(4)Serious carbon buildup on the piston ring. Excessive carbon deposits caused by the piston ring bonding or bite dead in the ring groove, while carbon is a hard abrasive, will be ground into longitudinal grooves in the cylinder wall.

(5)The piston is seriously off-cylinder. Due to the connecting rod bending and twisting deformation, connecting rod journal, the main shaft neck, piston pin seat parallelism and coaxiality deviation is too large, caused by the piston obvious cylinder, will accelerate the piston ring, piston and cylinder wall wear, damage to the formation of the oil film.

(6)The poor quality air filters. If the air filter filtration effect is not good, will cause the air in the dust, sand and other impurities into the cylinder, the formation of abrasive wear. Therefore, the air filter needs to be replaced in time.

(7)The use of poor quality oil oil viscosity or level selection is not appropriate. Oil quality has a relatively large impact on the oil film, viscosity is too low will make it difficult to form the oil film, or the oil film is too thin will increase the wear of the piston. Or the use of poor quality oil: poor quality oil impurities, impurities in the piston and cylinder wall friction caused by cylinder pulling.

4. How to prevent engine cylinder failure?

Method 1

For a new engine or an engine after overhaul, it must go through break-in first. Under the condition of good lubrication, according to the principle of rotational speed from low to high, load from small to large. Remember not to drive violently.

Method 2

Choose a matching, correct oil label; at the same time, check the engine oil level height at the right time, add oil in time when there is a loss of oil; replace the oil according to the normal cycle.

Method 3

To strengthen the maintenance and inspection of the excavator cooling system, it is recommended to clean the cooling system and radiator and water tank regularly. Engine overheating can also cause internal parts to expand and contract thermally, potentially increasing wear and tear between parts as they expand.